AMS, along with an ongoing partnership with Industrial Consultants, hosts quarterly safety training led by OSHA-accredited instructors at their corporate Woodridge headquarters and fabrications facility. This is only one part of our company’s commitment to safety, which stretches beyond compliance, by empowering both management and employees with comprehensive courses to prevent accidents and respond effectively in emergencies. We continually assess and update our training programs to align with industry best practices and evolving safety regulations.

There are multiple courses offered, not only to AMS employees, but to anyone industry-wide seeking to upskill, reskill, or enhance their expertise. AMS provides training for the following subjects below:

NH3 Emergency Response Training

The 24 Hour NH3 Emergency Response Training seminar, mandated by OSHA, is a pivotal event designed to equip participants with essential skills for handling hazardous chemical emergencies. Through a blend of theoretical instruction and practical application, attendees delve into OSHA’s HAZWOPER standard 1910.120(q), mastering protocols for managing chemical releases. Culminating in a live emergency response drill, participants put their knowledge to the test in simulated scenarios, bridging theory with real-world practice. This comprehensive program stands as a beacon of readiness, empowering individuals to confidently navigate emergency situations with skill and precision.

Annual Refresher/NH3 ERT Course

Graduates of the 24hr Emergency Response Team Training are also mandated to refresh their training, as required by OSHA for HAZWOPER Technician employees. In response, the 8 Hour Annual Refresher/NH3 ERT course was developed, tailored specifically for these individuals. This course integrates crucial classroom instruction with hands-on training to fulfill the refresher training obligations effectively. Through a comprehensive approach, participants ensure they maintain their expertise and adhere to safety regulations with diligence.

Incident Commander Training

Graduates of the 24hr Emergency Response Team Training could also further their knowledge with the 8 Hour Incident Commander training, tailored specifically for On Scene Incident Commanders. This specialized program recognizes their crucial role in taking control of incident scenes and offers comprehensive instruction to enhance their skills. Participants delve into essential topics including site control procedures, hazard assessment techniques, strategic response planning, and medical monitoring protocols, ensuring they are well-equipped to handle any emergency scenario with confidence and efficiency.

Process Safety/Risk Management Program

The 24 Hour Process Safety/Risk Management Program provides a thorough examination of OSHA’s Process Safety Management and EPA’s Risk Management Plan. Led by expert instructors, participants receive comprehensive classroom training on each PSM/RMP element, enabling them to effectively implement these programs at their respective facilities. By gaining essential knowledge and tools, attendees enhance their capacity to ensure safety and risk management protocols are successfully applied in their workplace environments.

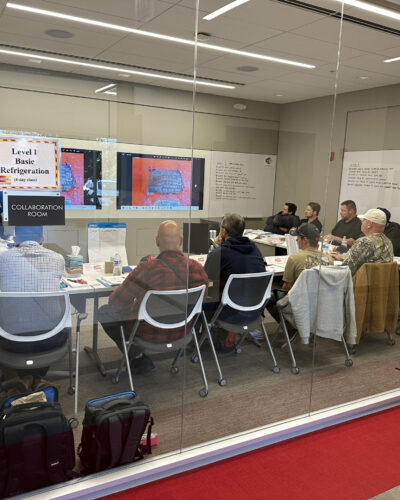

Level I Ammonia Refrigeration Operator Training

Designed for all personnel involved in ammonia refrigeration system operations, the 32 Hour Level I Ammonia Refrigeration Operator Training provides a comprehensive understanding of ammonia refrigeration principles, emphasizing hands-on proficiency in facility operating procedures; upon successful completion of the course, participants receive a certificate of completion following the examination at the end of class, with refresher training recommended every three years or as needed, tailored to the system’s complexity and operation.

Level A Suit Testing

Verifying the functionality of encapsulating Level ‘A’ Suits involves two crucial inspections: Visual Inspections and Air Pressure Tests, required upon receipt from the manufacturer, after each use, monthly, and annually. Our personnel conduct these inspections and tests according to ASTM F1052-14 Standards, repacking the suits, completing tags, and providing necessary documentation.

Respirator Fit Testing

A respirator fit test, mandated by OSHA 1910.134(f), determines if tight-fitting respirators can be worn without leaks, occurring after medical clearance and before work. Employees must wear a respirator matching the one for their job and any other necessary equipment during the test. Regular fit testing ensures an effective seal for proper protection against hazardous substances, promoting a safe working environment and ensuring employees are prepared to use respiratory protection equipment effectively.

These courses and others, are a major part of our partnership with Industrial Consultants. These training courses not only help ensure that all employees and tradespeople are up to date on all their certifications, but also helps to spread knowledge and safety proficiency throughout the industry. Safety and adequate training of employees is the backbone of AMS and a pillar of our core values, ensuring that we continue to be a leader in all the mechanical trades.